Air Filtration Device

Our Air Filtration Device is used extensively in areas such as shopping malls, restaurants, hotel kitchens and industrial kitchens and offers an effective solution in systems where welding fumes need to be filtered. This device significantly improves air quality by retaining particles down to 0.3 microns. The fan motor of the device is positioned outside the air flow, providing a more efficient performance.

Our device is equipped with metal, electrostatic and carbon filter systems that effectively remove up to 99% of odors and fat particles. Especially when used in charcoal or wood-fired cooking systems, it is mandatory to use a water filter device before the air filtration device.

Equipped with a full automation system, our device offers remote access and control over the internet thanks to the cloud system and can work in harmony with building automation systems. With its 50 mm thick double-walled rock wool filled panel structure, it offers high insulation and durability. In addition, high efficiency is achieved thanks to the plug fan system.

Depending on customer requirements, a UV lamp system can be added to the device, further improving air quality and neutralizing microorganisms. With its high efficiency and advanced features, this air filtration device significantly improves the air quality in kitchens and industrial areas and provides a healthy working environment.

General Features

- X Application Areas; It is used in shopping mall kitchens, restaurant kitchens, hotel kitchens, industrial kitchens and systems where welding fumes are required to be filtered.

- X Retains particles up to 0.3 microns.

- X The fan motor is kept out of the air flow.

- X Metal filter, electrostatic filter and carbon filter system eliminates odor and oil up to 99%. (In charcoal, wood-fired cooking systems, it is mandatory to use a water filter device before the air filtration device).

- X It has a full automation system and remote access and control over the internet is possible thanks to the cloud system. Compatible with building automation system.

- X The panel structure is 50 mm thick double-walled rock wool filled.

- X It has plug fan system.

- X UV lamp system can be used according to customer demand.

Material

|

|

Standard |

Option |

|

Outer Case |

Prepainted Galvanized Sheet |

AISI 304 quality stainless |

|

Inner case |

Galvanized Sheet |

AISI 304 quality stainless |

|

Panel Profile |

50 mm Aluminum Profile |

- |

|

Panel Filling |

70 kg/m3 Rock Wool |

- |

|

1st Stage Filter |

Metal Filter |

- |

|

2nd Stage Filter |

Electrostatic Filter |

- |

|

3rd Stage Filter |

Carbon Filter |

- |

|

4th Stage Filter |

- |

UV lamp |

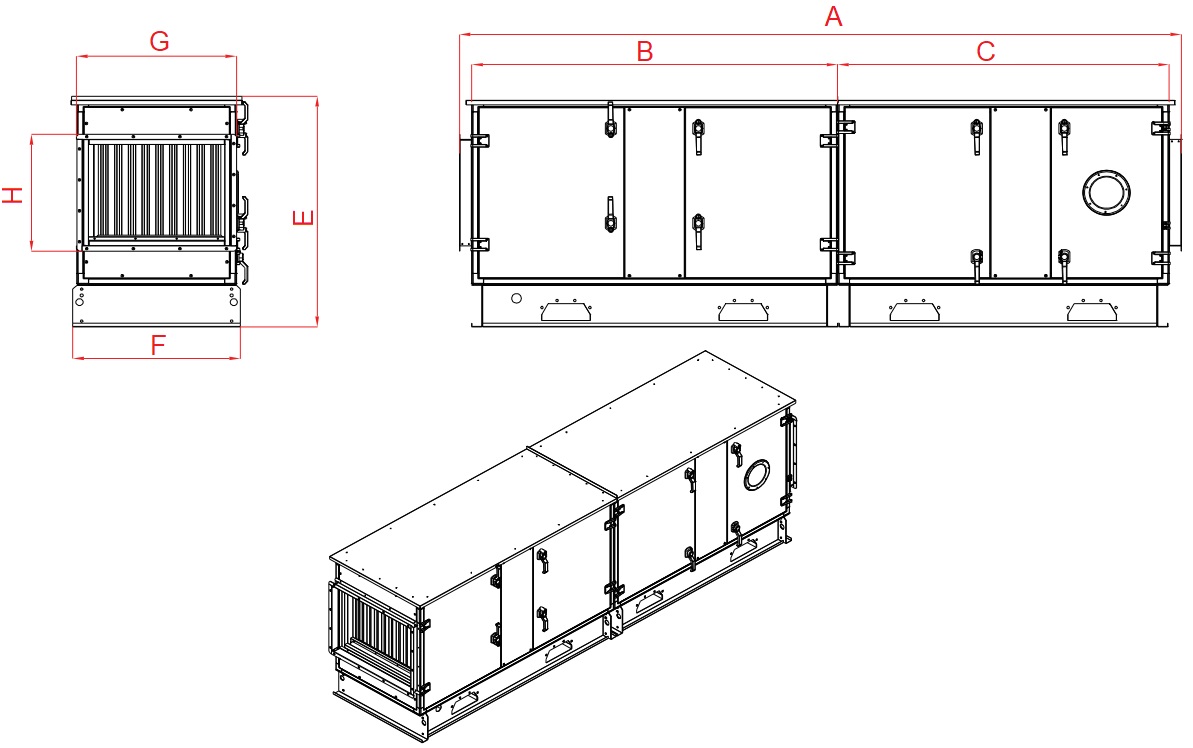

Dimensioning

Air Filtration Device

Model | Debi (m3/h) | A (mm) | B (mm) | C (mm) | G x H (mm) | E (mm) | F (mm) | Weight (kg) | Power (kW) |

X-HF-021 | 2100 | 4285 | 1650 | 1030 | 750 x 555 | 1495 | 756 | 460 | 2,07 |

X-HF-042 | 4200 | 4285 | 1650 | 1030 | 1020 x 555 | 1495 | 1055 | 760 | 3,92 |

X-HF-063 | 6300 | 4750 | 1960 | 1030 | 1330 x 1020 | 1650 | 1375 | 950 | 4,63 |

X-HF-084 | 8400 | 4750 | 1960 | 1030 | 1330 x 1330 | 1650 | 1375 | 970 | 6,77 |

X-HF-105 | 10500 | 4750 | 1960 | 1030 | 1640 x 1330 | 1650 | 1675 | 1100 | 7,36 |

X-HF-126 | 12600 | 4750 | 1960 | 1030 | 1950 x 1330 | 1650 | 1985 | 1500 | 8,89 |

X-HF-147 | 14700 | 4750 | 1960 | 1030 | 2260 x 1330 | 1650 | 2255 | 1850 | 11,66 |

X-HF-168 | 16800 | 4750 | 1960 | 1030 | 2570 x 1330 | 1650 | 2605 | 2000 | 11,84 |