Hepa Filter Box

The HEPA Filter Box is specially designed for use in pharmaceutical, chemical, and food industries, such as sterile environments, operating rooms, intensive care units, clean rooms, and water and beverage filling plants. It can be manufactured with side or top entry, low or high profile, depending on the project requirements, providing flexibility to meet different application needs. Hepa filter boxes are tested according to DIN 1946/4 standard and come with a 100% leak-proof guarantee. Equipped with differential pressure measurement ports to measure filter contamination, these boxes allow users to easily monitor the condition of the filters. Additionally, the internal structure of the box is highly resistant to disinfection processes, ensuring long-term and safe use.

General Features

- X The HEPA Filter Box is designed for sterile environments, operating rooms, intensive care units, clean rooms, and water and beverage filling plants (pharmaceutical, chemical, and food industries).

- X Custom manufacturing with side or top access, low-profile or high-profile designs.

- X All HEPA filter boxes have been tested according to DIN 1946/4 and are offered for use with a 100% leak-proof guarantee.

- X It has differential pressure measurement tips for measuring filter contamination.

- X The inside of the box is resistant to disinfection processes.

Material

- STANDARD:

- X DKP Hair Manufacturing

- OPTIONAL:

- X 304 and 316 Grade Stainless Steel

Case Types / Dimensioning

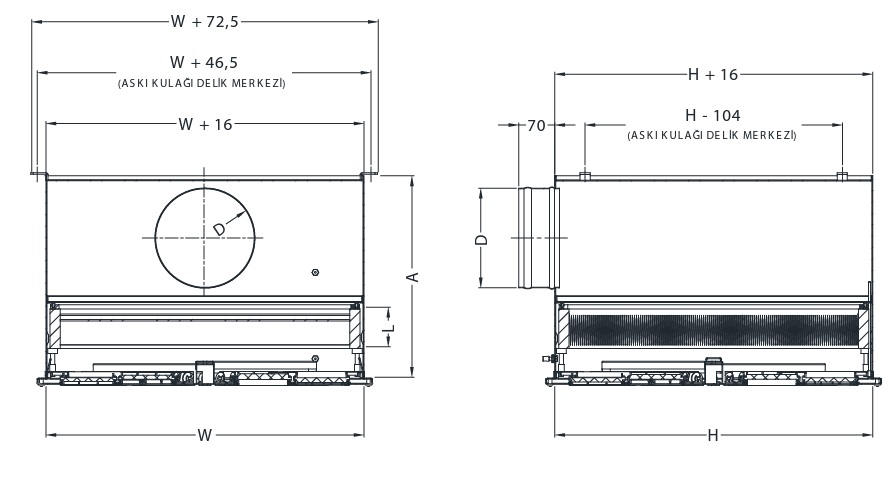

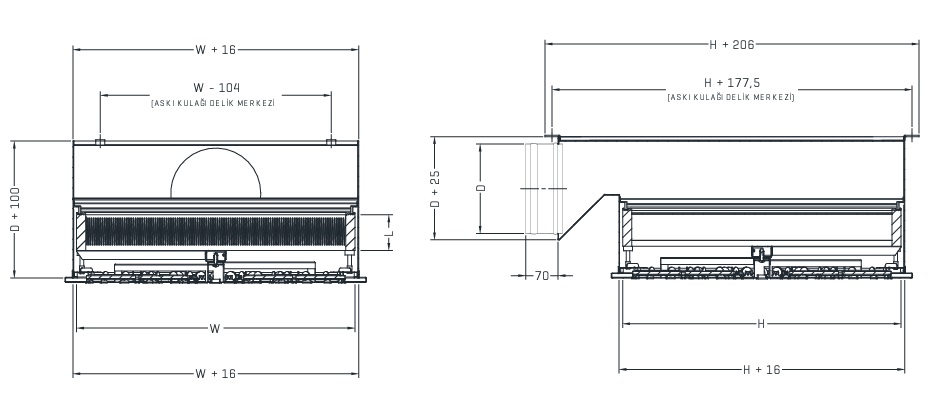

Channeled HEPA Filter Box (Type 1)

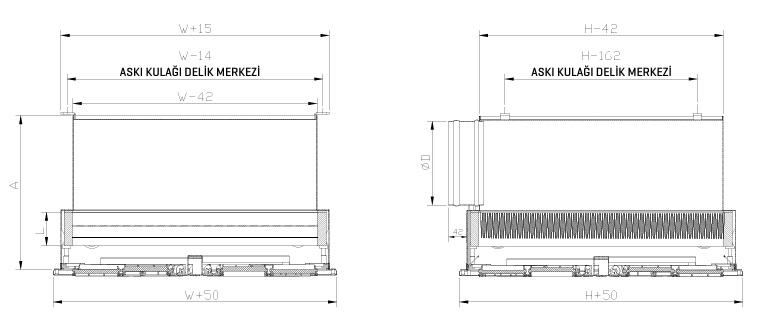

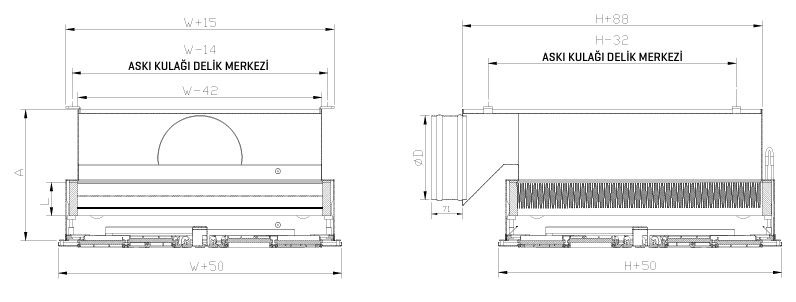

Flat Seating Surface HEPA Filter Box (Type 2)

| |

305 x 305 x 78 – Ø125 | 305 x 305 x 149 – Ø125 |

457 x 457 x 78 – Ø160 | 457 x 457 x 149 – Ø160 |

535 x 535 x 78 – Ø180 | 535 x 535 x 149 – Ø180 |

575 x 575 x 78 – Ø200 | 575 x 575 x 149 – Ø200 |

610 x 610 x 78 – Ø200 | 610 x 610 x 149 – Ø200 |

Surface Coating

- STANDARD

- X RAL 9010 or RAL 9016 Electrostatic Powder Coating

- OPTIONAL

- X Different RAL color codes

- X Unpainted manufacturing

Election Table

The filter intake velocity is 0.45 m/s and can exceed the maximum flow rate by +10%.Filter Size (mm x mm x mm) | Pile Height (mm) | Max Flow Rate (m3/h) | H13 Initial Pressure Loss | H13 Final Pressure Loss | H14 Initial Pressure Loss | H14 Final Pressure Loss |

305 x 305 x 78 | 50 | 150 | 100 Pa | 200 Pa | 125 Pa | 250 Pa |

457 x 457 x 78 | 50 | 340 | 100 Pa | 200 Pa | 125 Pa | 250 Pa |

535 x 535 x 78 | 50 | 465 | 100 Pa | 200 Pa | 125 Pa | 250 Pa |

575 x 575 x 78 | 50 | 535 | 100 Pa | 200 Pa | 125 Pa | 250 Pa |

610 x 610 x 78 | 50 | 600 | 100 Pa | 200 Pa | 125 Pa | 250 Pa |

305 x 305 x 149 | 125 | 150 | 55 Pa | 110 Pa | 70 Pa | 140 Pa |

457 x 457 x 149 | 125 | 340 | 55 Pa | 110 Pa | 70 Pa | 140 Pa |

535 x 535 x 149 | 125 | 465 | 55 Pa | 110 Pa | 70 Pa | 140 Pa |

575 x 575 x 149 | 125 | 535 | 55 Pa | 110 Pa | 70 Pa | 140 Pa |

610 x 610 x 149 | 125 | 600 | 55 Pa | 110 Pa | 70 Pa | 140 Pa |

Accessories

- X Column Valve

- X Square Anemostat

- X Perforated Vent