Circular CAV Device

The Circular CAV Device is used to control airflow in projects requiring comfort and hygiene, such as operating rooms, clean rooms, and specialized processes. Airflow can be easily adjusted using an Allen wrench on the device. This device can balance the pressure in the air duct between 20 Pa and 1000 Pa and, as it is a completely mechanical system, does not require any additional power input. Depending on pressure changes in the duct, when the CAV blade's torque decreases, the blade opens and the air flow rate increases; when the torque increases, the blade closes and the flow rate decreases. Thanks to the calibration spring, the CAV operates effectively at the calibrated flow rate with a deviation rate of 10-20%. It features a specially designed air viscous piston to reduce blade oscillations at high pressures. It is designed in accordance with DIN EN 1946/4 and VDI 6022 hygiene standards.

General Features

- X Used in projects with special requirements such as comfort and hygiene, such as operating rooms, clean rooms, and special processes, to control air flow.

- X The desired air flow rate can be easily adjusted using an Allen wrench on the device.

- X It can balance the pressure in the air duct between 20 Pa and 1000 Pa.

- X Since it is a completely mechanical system, it does not require any power input. Stabilization of the air flow rate is based on counteracting pressure changes in the system. When the air flow rate decreases due to pressure and pressure-related factors in the channel, the torque acting on the CAV flap decreases and the flap opens. As the blade opens, the air flow rate through the channel increases and returns to the calibration value.

- X Conversely, when the air flow rate increases, the torque acting on the blade increases and the blade closes. When the blade closes, the air flow rate through the channel decreases and returns to the calibration value.

- X The mechanism, precisely designed with a calibration spring according to the position of the blade, ensures that the CAV operates successfully with a deviation rate of 10-20% at the calibrated flow rate.

- X It features a specially designed air viscous piston to minimize blade vibrations caused by increased turbulence at high pressures.

- X Complies with DIN EN 1946/4 and VDI 6022 hygiene standards.

Material

- STANDARD: X Galvanized steel casing and vane X Plastic adjustment tube for flow calibration. X Stainless steel calibration spring X EPDM rubber channel gaskets X Vane shaft AISI 304 stainless steel, shaft bushing PTFE plastic

- OPTIONAL: X Stainless coated steel case and sash

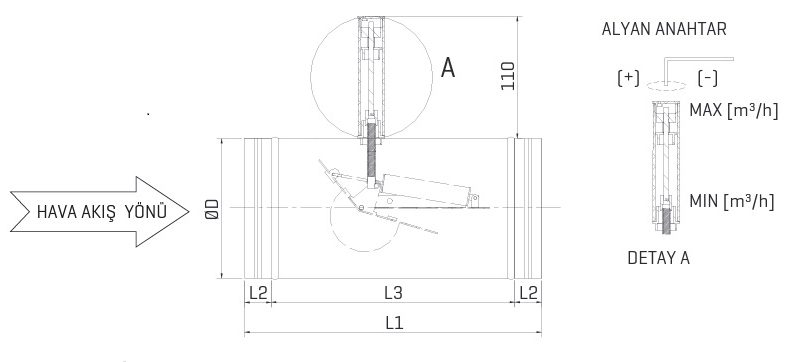

Case Types / Dimensioning

SIZE | ØD (mm) | L1 (mm) | L2 (inches) | L3 (mm) | V min (m3/h) | V max (m3/h) |

Ø100 | 98 | 240 | 50 | 140 | 85 | 254 |

Ø125 | 123 | 240 | 50 | 140 | 132 | 397 |

Ø150 | 148 | 240 | 50 | 140 | 191 | 572 |

Ø160 | 158 | 250 | 50 | 150 | 217 | 651 |

Ø200 | 198 | 280 | 50 | 180 | 339 | 1017 |

Ø250 | 248 | 280 | 50 | 180 | 530 | 1590 |

Ø300 | 298 | 380 | 50 | 280 | 763 | 2289 |

Ø315 | 313 | 380 | 50 | 280 | 841 | 2524 |

Ø355 | 353 | 450 | 50 | 350 | 1068 | 3205 |

Ø400 | 398 | 450 | 50 | 350 | 1356 | 4069 |

Surface Coating

- STANDARD: X Galvanized Case

- OPTIONAL X

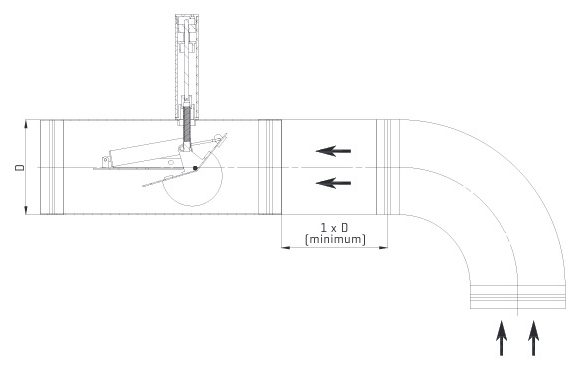

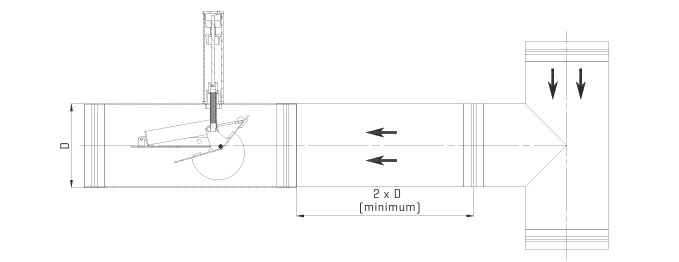

Assembly Detail

Minimum channel length after bends

Te - Minimum channel length after reduction etc. channel equipment

Accessories

- STANDARD: X Electric Heater

- OPTIONAL: X Circular Silencer